Artificial intelligence (AI) is seemingly everywhere and is supposed to help with everything. But does it also work in the wiring system industry? LEONI investigates where and how AI can support its daily work – at times with surprising findings.

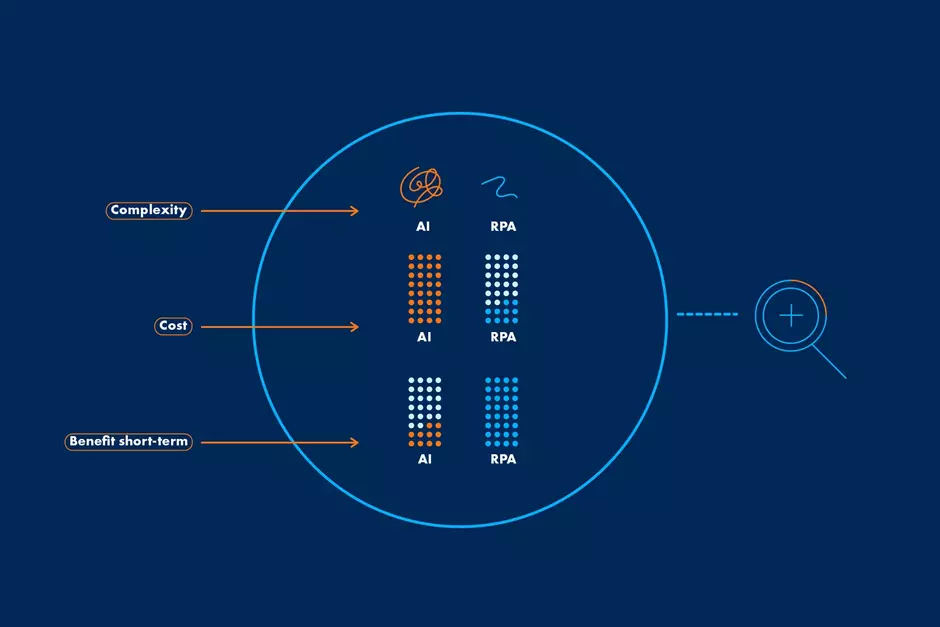

In 2018, at the height of the hype around Deep Learning (a form of AI), we started researching possible use cases for AI. However, conversations with employees revealed that they hardly saw a need for AI. Rather, they wanted rule-based process automation to relieve the back-office organization of time-consuming routine tasks. The "low-hanging fruits" for their day-to-day work were more important to them than fancy high-tech applications.

This answer was initially surprising to me as an AI proponent, but it was logical. After all, compared to AI, rule-based process automation (also known as Robotic Process Automation, RPA) is easier and cheaper to implement and also had a higher short-term benefit for us. So we first developed the topic of RPA into a global service within LEONI.

Once the RPA service was established, we launched a second AI investigation balloon. At a cross-departmental workshop, we explained the basics of AI to LEONI employees and discussed their ideas and potential with them. And lo and behold, some realistic application possibilities emerged.

What is AI anyway?

Before describing our first AI pilot application, it makes sense to take a look at AI itself. Only when you understand AI and its limits and also recognize your own application possibilities, then AI turns from an unreflected "hype" into a realistic "hope".

To start, not all AI is the same. For example, it works with many different file formats as input data, which means that it often looks very different in the application. For instance, sales forecasts are based on numbers, quality control relies on images, and certain automation processes handle text. Moreover, people do not always have the same conceptions about AI.

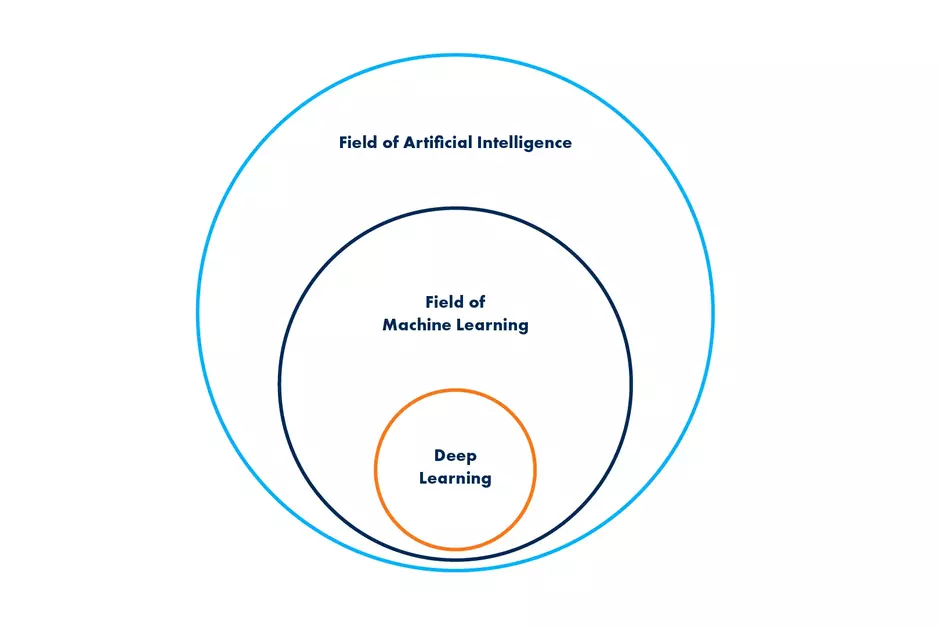

This is no wonder, as there are different subfields within AI with different areas of application.

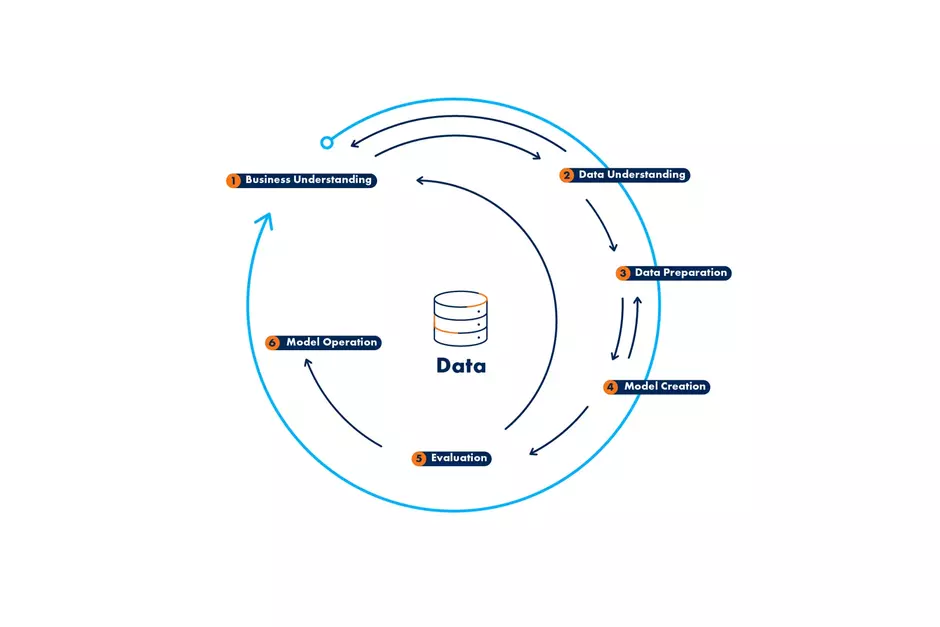

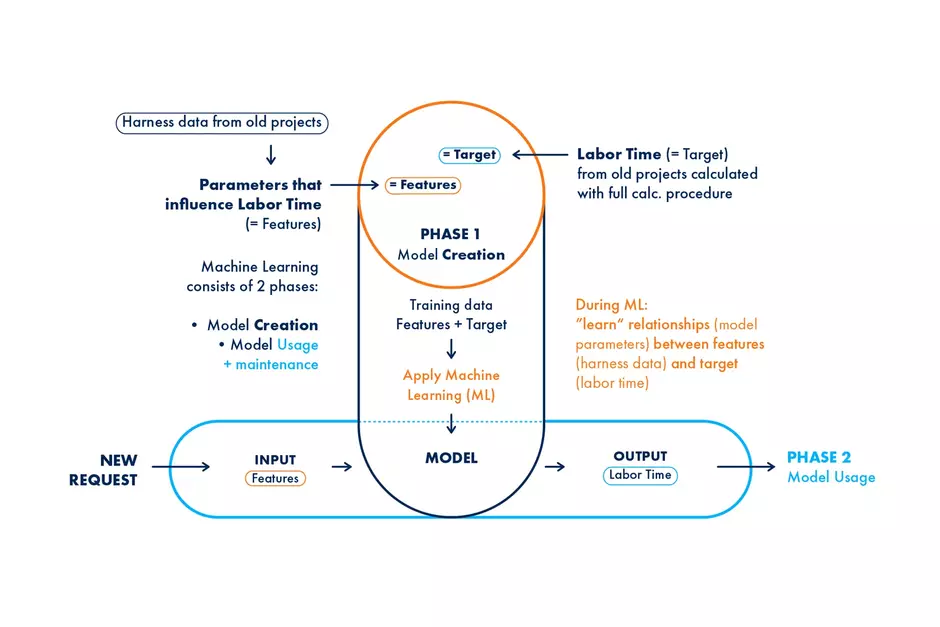

One subfield of AI is machine learning (ML), in which data is used in a first phase to develop a model (model creation, see steps one through four in Figure 3). This phase includes the understanding of the business problem as well as the understanding and preparation of the relevant data. If the model adequately solves the problem, it is used in the day-to-day operations during the second phase in which, if necessary, it can be optimized continuously as well (steps five and six).

Without AI, we'd be out - Responding faster to the customer's request

In the past, a particular customer would send us a request with a drawing and a wire list of the desired harness and we would calculate the costs within some weeks. Today, the customer's deadlines for submitting an initial indicative offer are much shorter. If we do not submit an offer, we are already eliminated at the beginning of the offer process.

In our pilot project, we focused only on one cost factor that was time-consuming to get, namely the labor time to produce a harness. To solve such a supervised machine learning regression problem, we needed two data inputs for the model creation: the labor time (target) and its influencing factors (features, cf. Fig. 4 ). As influencing factors, we defined data about the harness that was relevant to predicting labor time and was available quickly – such as the number and length of wires, the number of connectors, etc. After selecting and collecting these features from old projects, we now needed to add the correct labor times from the normal (full) calculation processes to complete the training data. During machine learning, the relationships (model parameters) between the features (influencing factors) and the target (labor time) are then "learned". This simply means that different mathematical models (ML algorithms) are tried on the training data to find the best model that minimizes the error between model prediction and actual labor time. If the model is accurate enough, it can give a recommendation for answering a new request. All that is needed are the influencing factors.

How well does the predictive model actually work?

In our case, we used the data from about 200 harnesses from the past during the training phase to select the best model from a variety of models. We then fed this model with data from about 50 other past wiring harness projects and then tested its accuracy. In this validation phase, the model made predictions solely based on the learned training data and without human intervention. Here are the results:

- For the validation dataset, the AI model predicted labor times that had a mean absolute error of 4.1 minutes (the mean true labor time was about 58 minutes). For large harnesses, this is already quite good. For small harnesses, on the other hand, the model still needs to be improved, since the percentage error increases for small harnesses.

- In a separate test run with data from a new request with eight harnesses (average labor time 237 minutes), the mean percentage error was about 10%. Only for one harness with more than 400 minutes of true labor time, the prediction was off by more than 20%. The reason for this lies in the training data for the model: no comparably large harness was present during training.

During model development and use, we became aware of a few aspects concerning AI:

- If the training data for model development in phase one is poor, the model prediction in phase two will also be poor.

- If the training data from phase one differs greatly from the data of the new request in phase two, the AI results may also be unreliable.

- RPA and AI benefit from each other. Where RPA is in use, process data can be automatically saved and used for model training (RPA, the data collector). Conversely, AI expands the (purely rule-based) scope of RPA through its own capabilities and thus the number of processes that can be automated, e.g., by 'understanding' an email.

- If one wants to improve the accuracy of an ML model, having better and more data usually gives one more leverage than tuning the model for the umpteenth time. By collecting new data sets, a larger and larger data pool can be made available to the model.

- It is recommendable to start with a simple and manageable pilot application.

What's next for AI? What do we expect in the future?

On the one hand, we at LEONI have other applications in mind, both based on numbers, for different types of forecasts, and on image data, for example quality control. On the other hand, we are also thinking about the use of Large Language Models. For example, we asked OpenAI's GPT-4 model, which is built into Microsoft's Bing search engine, to generate the necessary software code for model generation and evaluation for the labor time use case mentioned earlier. To our delight, GPT-4 did indeed generate the Python code. Of course, it should be used with caution. One should know well what pitfalls and gaps the results of AI-generated text or code may have. But there is a real opportunity to use AI to generate AI code - in fact, much faster than before.

The benefits of AI in the future? That's hard to predict. At LEONI, we've found the first applications for AI. Find yours!

Do you have a question?

We’ll be glad to help. We look forward to hearing from you.

Michael Grade

Lead Expert E/E System Architecture